Good news! Our HZZG has recently made another breakthrough in the field of technology. We have successfully installed an explosion-proof device for our customers to meet the needs of coal mining. In response to this breakthrough, we at HZZG will introduce to you what explosion-proof devices are and what kind of working conditions require the installation of such devices.

In hazardous environments like the chemical, petroleum, and pharmaceutical industries, where flammable and explosive materials are present, forklifts, as crucial material handling equipment, have a direct impact on production safety and the lives of employees. Explosion-proof devices installed on forklifts act like a protective shield, effectively preventing explosions caused by forklift operation and playing a key role in ensuring safe operations in hazardous environments.

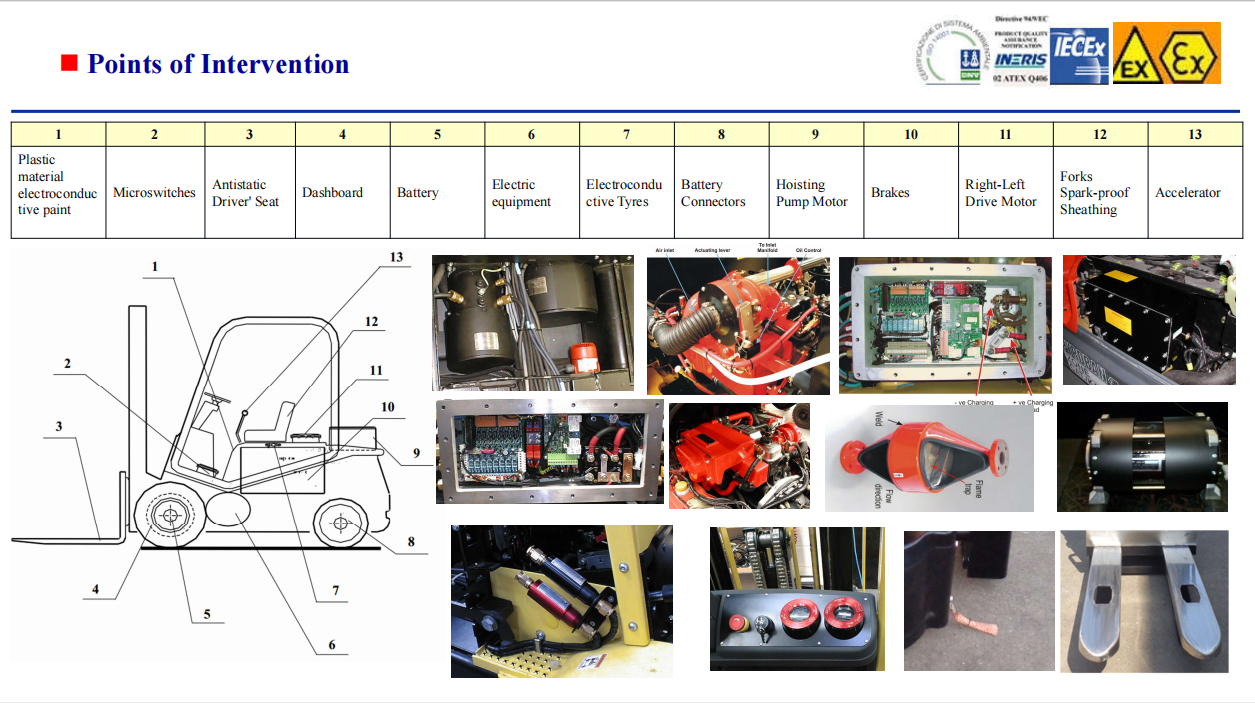

The core function of explosion-proof devices is to suppress or eliminate potential ignition sources during forklift operation, such as sparks and hot surfaces, thereby preventing these ignition sources from reacting with flammable and explosive gases and dust in the surrounding environment and causing an explosion. A complete forklift explosion-proof system is not a single component, but rather a system comprised of multiple key components working together.

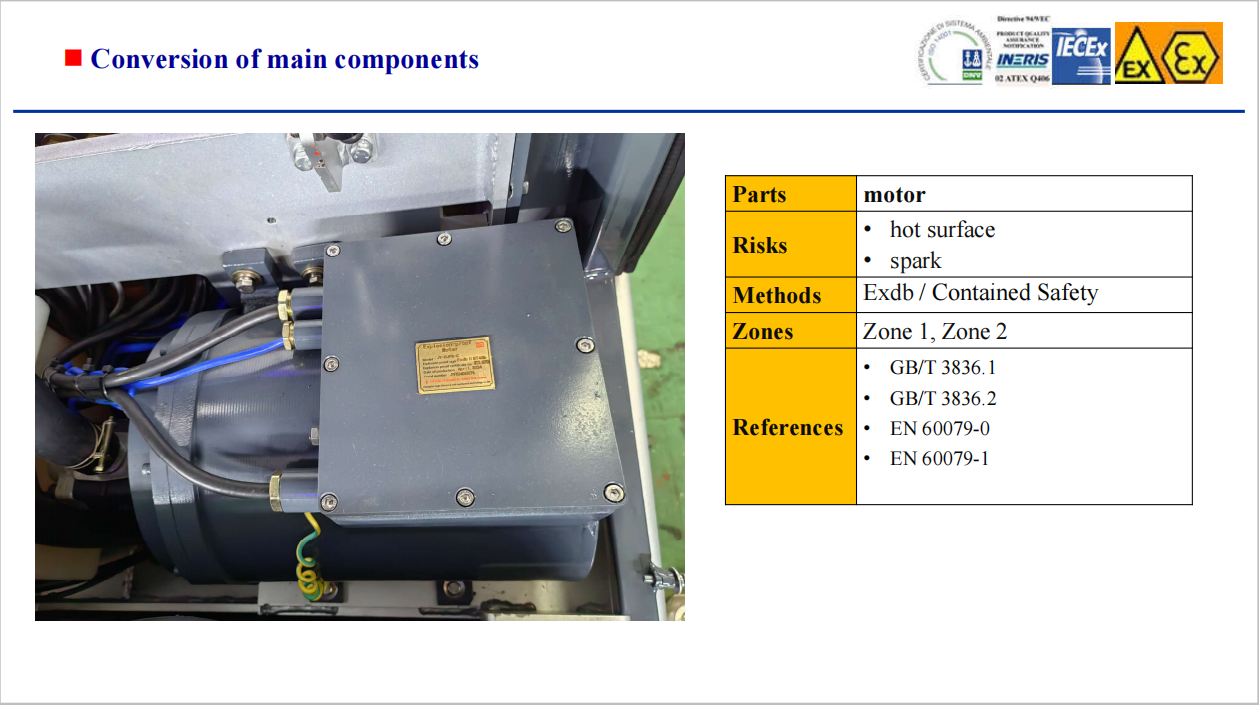

The explosion-proof motor is the core power component of a forklift explosion-proof system. When operating, conventional motors are prone to sparks between the brushes and commutator, posing a significant safety hazard in hazardous environments. Explosion-proof motors, however, utilize specialized structural designs, such as flameproof enclosures, to contain potential sparks and arcs within the motor, preventing them from coming into contact with flammable and explosive materials. At the same time, the windings, insulation and other materials of the explosion-proof motor have also undergone special treatment to have higher heat resistance and stability, ensuring safe operation in high temperature environments.

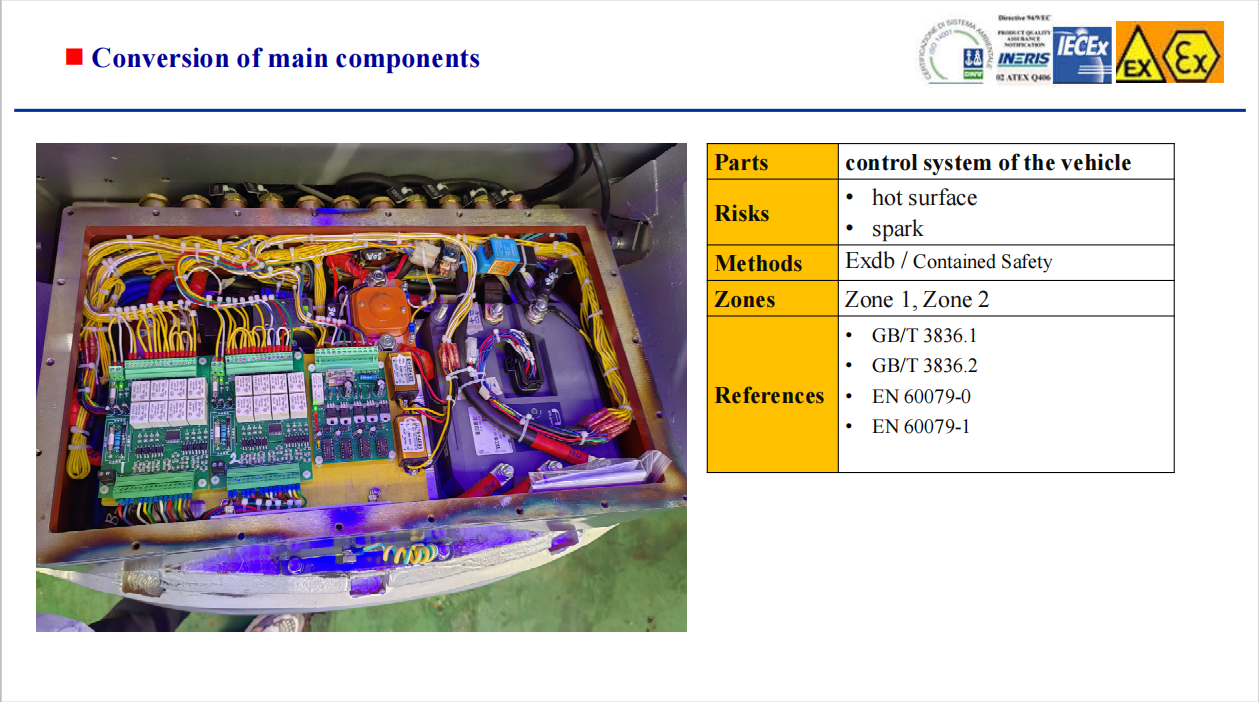

The explosion-proof controller acts as the forklift’s “brain,” controlling its movements, including travel and lifting. It utilizes an intrinsically safe design, with circuitry that strictly limits current and voltage to prevent sparks from circuit failures. Furthermore, the explosion-proof controller includes overcurrent, overvoltage, and short-circuit protection features, quickly shutting off power in the event of an abnormality to prevent further damage.

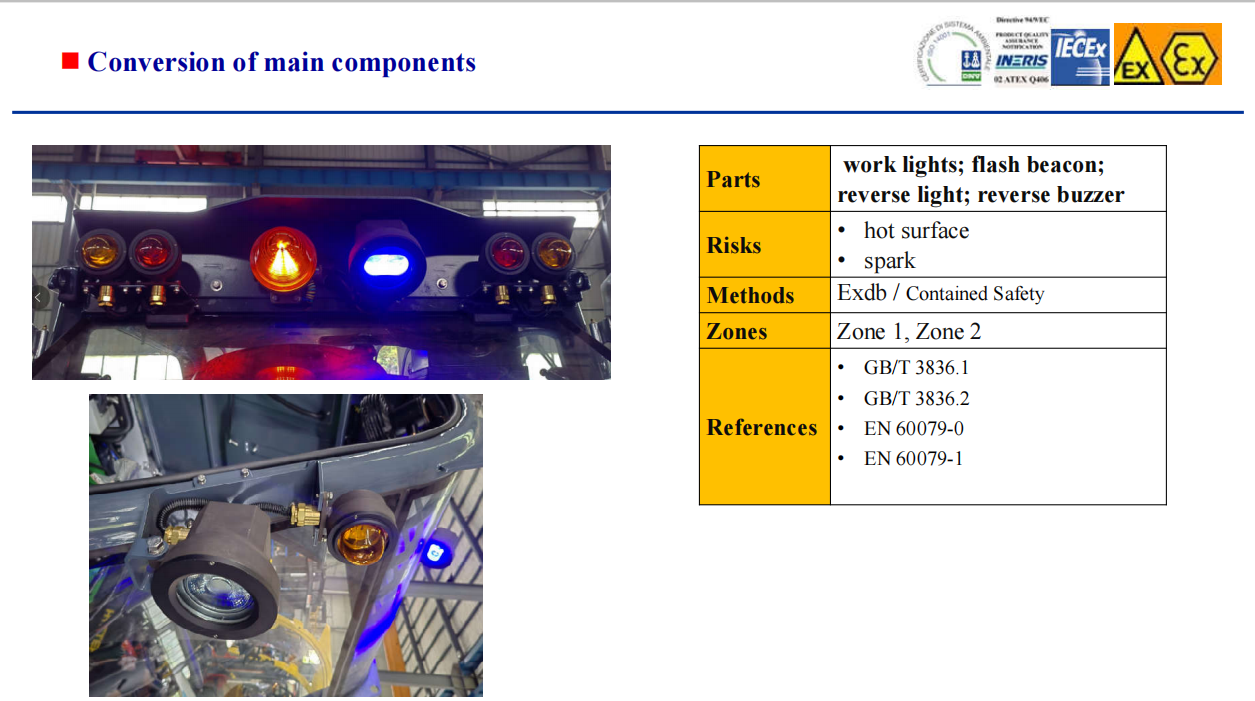

In addition to the core motor and controller, forklift explosion-proof systems also include auxiliary components such as explosion-proof lamps, explosion-proof instruments, and explosion-proof switches. Explosion-proof lamps utilize a flameproof structure to ensure that the lighting process does not generate sparks or high temperatures sufficient to ignite flammable and explosive materials. Explosion-proof instruments accurately display various forklift parameters in hazardous environments, and their casings are explosion-proof. Explosion-proof switches utilize special sealing and flameproof designs to ensure safety during operation. Some example pictures:

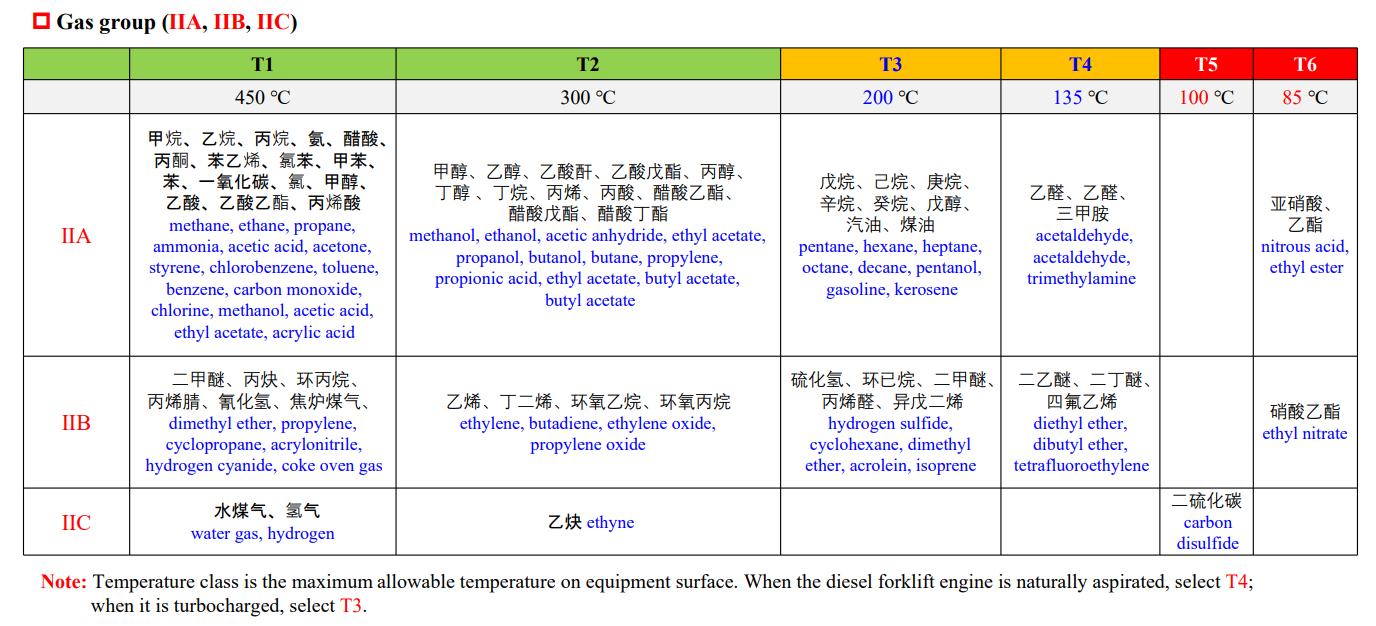

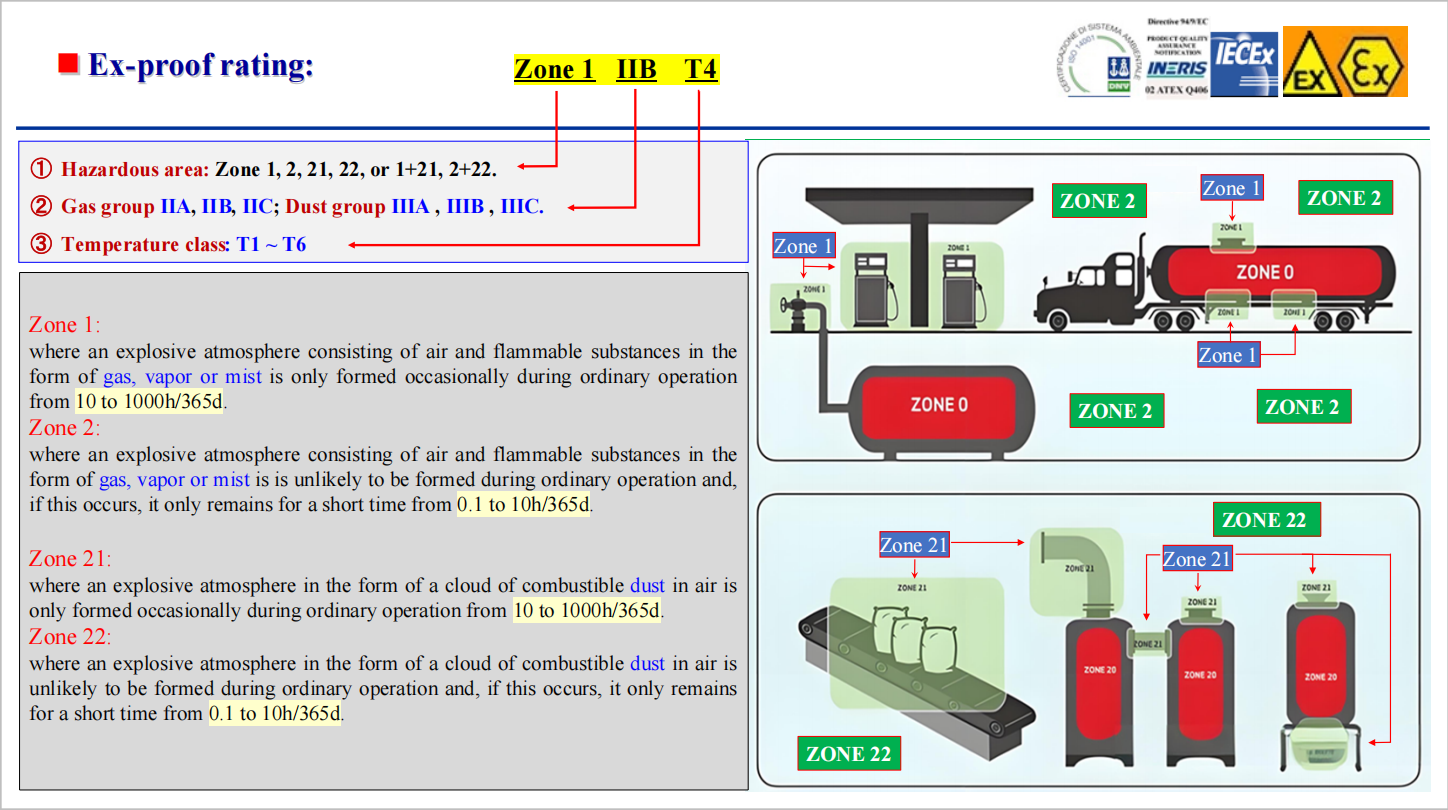

To ensure that forklift explosion-proof devices function effectively, their installation must strictly adhere to relevant specifications and standards. Before installation, the forklift’s overall structure must be evaluated, and appropriate explosion-proof components must be selected based on the forklift’s model, power, and other parameters. During installation, tight connections and proper sealing must be ensured between explosion-proof components to prevent the ingress of flammable and explosive materials. After installation, rigorous testing and commissioning, including explosion-proof performance testing and operational stability testing, are required. Only forklifts that pass these tests can be put into operation. “Determination of Dangerous Goods Level” as follows:

With increasing industrial safety requirements, forklift explosion-proof devices are also undergoing continuous development and innovation. New explosion-proof technologies are constantly emerging, further improving the safety and reliability of forklifts in hazardous environments. Furthermore, intelligent explosion-proof monitoring systems are also being incorporated into forklift explosion-proof devices. These systems monitor the forklift’s operating status and the concentration of flammable and explosive substances in the surrounding environment in real time, providing prompt alerts and enabling appropriate action if any anomalies are detected. Our factory possesses comprehensive certifications, ensuring peace of mind and providing added assurance for safe operations in hazardous environments.

In short, explosion-proof devices installed on forklifts are a crucial barrier to ensuring safety in hazardous environments. Through a series of scientifically sound designs and technical measures, they effectively prevent explosion accidents. In industrial production, prioritizing the selection, installation, and maintenance of forklift explosion-proof devices is crucial for ensuring safe production and the safety of personnel.

If you have any needs, please feel free to contact our HZZG sales staff. We are very willing to answer your questions and are always waiting for your consultation!