The Real Cost of That Puddle on Your Warehouse Floor

Let’s be honest: nobody walks into a warehouse, sees a puddle of hydraulic fluid under a parked forklift, and thinks, “That’s no big deal.” We all know what that spot means. It means downtime. It means a safety hazard that OSHA hates. And mostly, it means you’re losing money every second that machine isn’t lifting a pallet.

In this business, the hydraulic system is the muscle of your operation. If the engine is the heart, the hydraulics are the arms and legs. When you lose pressure, you lose the ability to work. I’ve seen fleet managers ignore a “weeping” cylinder for weeks because they didn’t want to pull the unit off the line. Fast forward a month, and that minor seal leak turned into a scored piston rod and a contaminated pump, turning a $50 seal replacement into a $2,000 catastrophe.

The reality is that hydraulic leaks are rarely just about the oil. They are a symptom of something else going wrong—whether it’s operator abuse, bad fluid maintenance, or seals that just couldn’t take the heat. If you are running serious equipment, like the heavy-duty Hezhong Balance Forklift Truck, you expect it to perform. But even the best iron needs the right care. In this guide, we aren’t just going to talk about how to swap a seal; we’re going to dig into why these leaks happen and how you can stop chasing your tail with repairs.

What’s Actually Happening Inside the Cylinder?

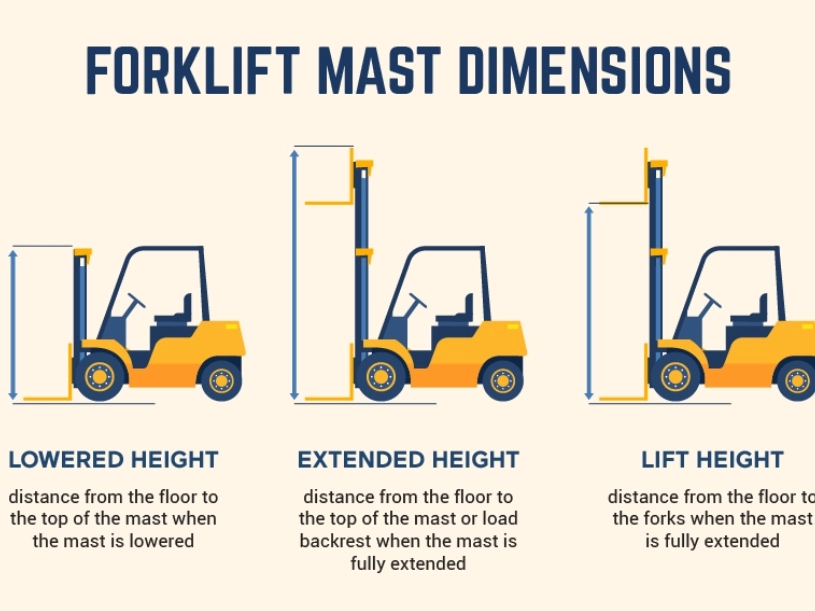

To fix it, you have to understand it. You don’t need a physics degree, but you do need to know what’s keeping that oil inside. A hydraulic cylinder is basically a pressure vessel. You’ve got a piston rod moving in and out of a barrel thousands of times a shift.

The magic happens at the “gland”—the cylinder head. This is where the rod exits the barrel. Inside that gland, you have a stack of seals working together.

-

The Wiper: This is the bouncer at the door. Its job is to scrape dirt and dust off the rod as it retracts so that grit doesn’t get inside the oil. If your wiper is cracked, the war is already lost.

-

The Rod Seal: This does the heavy lifting. It holds the high-pressure fluid back. If you see oil dripping down the chrome rod, this seal is toast.

-

The Buffer Seal: This sits behind the rod seal and protects it from massive pressure spikes—like when an operator drops a load too fast.

Then you have the Piston Seal deep inside. You can’t see this one. If it fails, oil bypasses the piston head internally. The rod won’t leak on the floor, but your forks will “drift” or sink slowly when holding a load. That’s a ghost leak, and it’s just as dangerous.

Why Good Cylinders Go Bad: The Usual Suspects

I’ve torn down hundreds of cylinders, and the cause of failure almost always falls into one of three buckets. It’s rarely a “defective part”—it’s usually how that part was treated.

The “Sandpaper” Effect (Contamination)

Hydraulic fluid should be clean enough to eat off of. But in a warehouse, dust is everywhere. If your breather cap is clogged or someone used a dirty funnel to top off the tank, you’ve introduced grit into the system. Those microscopic particles get trapped between the seal and the chrome rod. Every time the cylinder strokes, that grit acts like sandpaper. It eats the seal lip alive. Once the lip is gone, the oil follows.

Rod Damage: The Scar That Kills

Go look at your forklifts. Run your fingernail along the chrome piston rod (safely, when it’s off). If your fingernail catches on a scratch, a ding, or a pit of rust, that cylinder is a ticking time bomb. A rough spot on the rod acts like a serrated knife. You can put the most expensive, high-tech seal in the world on that machine, and that scratch will slice it open in five minutes. This usually happens from side impacts—bumping the mast against racking—or leaving machines outside where moisture pits the chrome.

Cooking the Seals (Heat)

Hydraulics run hot. But if they run too hot—say, over 180°F—things get ugly. Standard seal materials like nitrile rubber start to bake. They lose their stretch. Instead of being rubbery and compliant, they turn into hard plastic. A hard seal can’t follow the shape of the rod, and the fluid slips right past. This happens when you work a machine beyond its duty cycle or if the cooling system is clogged with warehouse fluff.

Troubleshooting: Don’t Guess, Diagnose

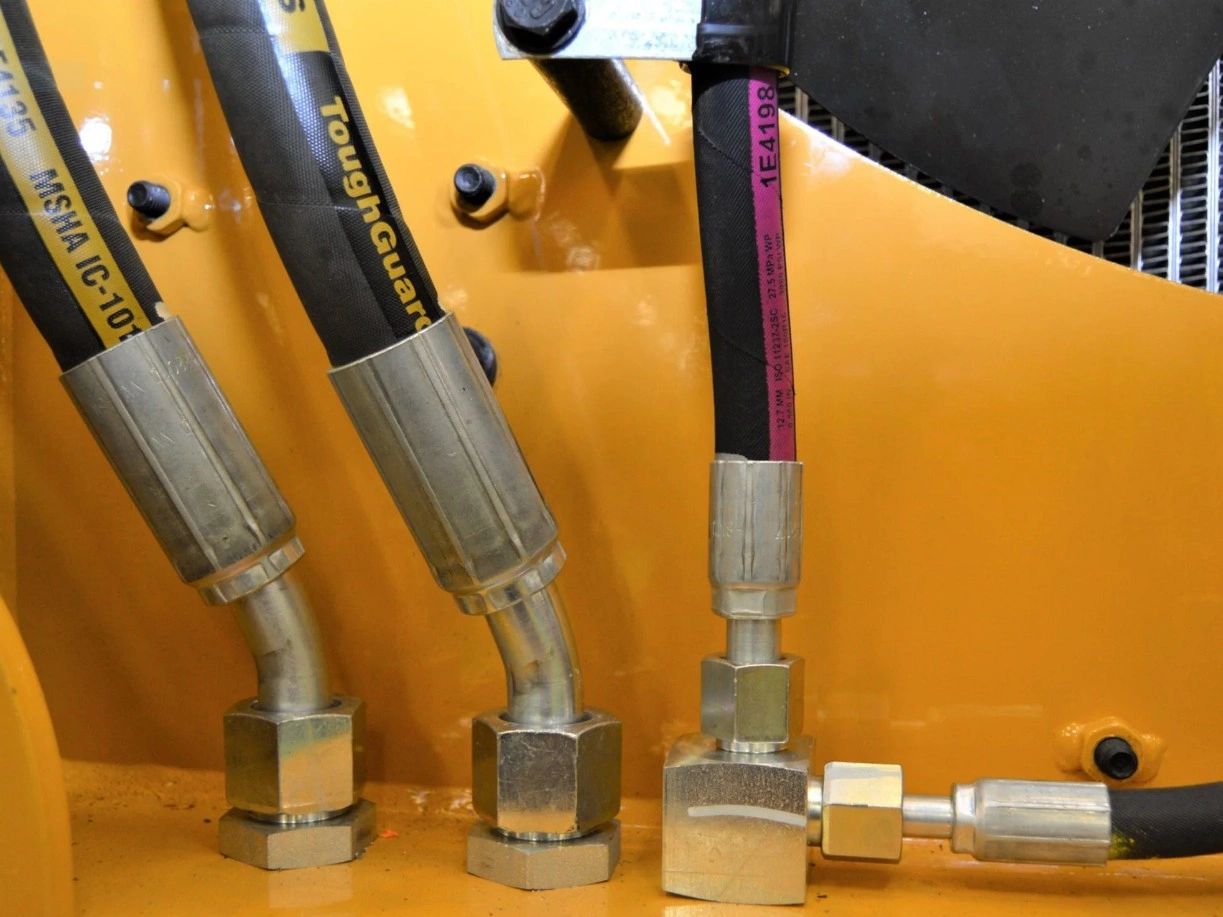

Before you order parts, stop. I’ve seen guys replace a $500 cylinder because they thought it was leaking, only to find out later it was a $20 loose hose fitting dripping onto the cylinder.

Step 1: The Clean Up Grab some degreaser and rags. Clean that cylinder until it looks new. You can’t track a leak through layers of grease sludge.

Step 2: The Cycle Test Start the machine. Raise the forks to the limit (safely) and hold it against the relief valve for a second. Then lower it. Do this a few times. Watch the gland nut area.

-

Oil coming from the rod wiper? Your rod seal is blown.

-

Oil coming from the threads of the cylinder head? The static O-ring on the gland is shot.

-

No oil, but the forks are dropping? That’s an internal piston seal failure.

Step 3: The “Finger” Test Check the rod surface again. If the rod is bent or scored, do not just reseal it. I repeat: do not just reseal it. You are wasting your time. A damaged rod will kill the new seal immediately. If the hard parts are bad, you need a new cylinder or a machine shop.

The Decision: Rebuild Kit vs. New Iron

This is the question every maintenance manager asks me: “Is it worth fixing?”

Here is my rule of thumb. If the machine is relatively new and the chrome rod is perfect—mirror finish, no scratches—then buy a seal kit. It’s cheap, and if you have a decent mechanic, they can swap it out on the bench in an hour.

But, if the rod is pitted, or if the cylinder barrel looks ballooned (which happens from overloading), throw it in the scrap bin. The labor cost to tear it down, hone the barrel, and re-chrome the rod often costs more than just buying a replacement unit. Plus, with a new unit, you get a warranty.

If you are running a mixed fleet, standardization helps. High-quality equipment, like the models found in the Hezhong Product Center, is designed with serviceability in mind. When you buy from a manufacturer that uses standard, high-grade components, finding a seal kit five years down the road is a lot easier than hunting for parts for some “mystery machine.”

Prevention: How to Keep the Floor Dry

You want to stop leaks? Change your habits.

Filter Carts are Your Friend: Don’t just dump oil from a bucket into the tank. Use a filter cart. New oil from a drum isn’t actually “clean” enough for high-pressure hydraulics.

The Pre-Shift Walk: Make your operators look at the cylinders. If they see a nick in the chrome, they need to report it. A tiny burr can be filed down smooth before it kills the seal. If they ignore it, it becomes a leak.

Stop Bottoming Out: Teach operators not to slam the forks to the very top or bottom of the lift range at full speed. That “bang” you hear? That’s a pressure spike trying to blow the seals out of the gland.

Manufacturing Matters: The Hezhong Difference

A lot of hydraulic problems start at the factory. If the tolerances aren’t tight, or if the metal isn’t heat-treated right, you’re fighting a losing battle. This is where the source of your equipment matters.

Take Qingdao Hezhong Machinery Manufacturing Co., Ltd. for example. We aren’t just assembling parts; we are engineering solutions. We’ve been at this since 2007, operating out of the Ashes Industrial Park in Pingdu, Qingdao. When you have a facility covering 50,000 square meters and a team of over 400 people, you aren’t guessing.

We have 55 engineers dedicated specifically to product innovation. That means when we design the hydraulic system for our CPY Series or the ZL wheel loaders, we are calculating the stress loads, the thermal expansion, and the seal compatibility long before the metal is cut. We produce over 15,000 units a year , and every single one has to pass strict quality controls like ISO 9001 and CE.

We believe in the philosophy that “Technology produces quality”. That’s why our cylinders hold up in the dust of a brickyard or the heat of a foundry. We build them to handle the abuse because we know what the real world looks like. If you want to see exactly how we build them, check out the Acerca de nosotros page. We welcome partners to visit the factory—seeing the assembly line usually answers any questions about quality.

Conclusión

Hydraulic leaks are a pain, but they are manageable. It comes down to discipline. Keep your oil clean, keep your rods smooth, and fix the small weeps before they turn into gushers. And when it comes time to buy new gear, look for manufacturers who put as much thought into the hydraulic engineering as they do the paint job. Your maintenance budget will thank you.

If you need help upgrading your fleet to something that stays dry and keeps lifting, reach out to us at Hezhong Machinery. We’ve been helping businesses move heavy loads for nearly two years—wait, nearly two decades. (Since 2007, to be exact ).

Frequently Asked Questions (FAQs)

Q1: Why does my forklift drift down when I leave a load raised overnight?

This is almost always an internal leak, not an external one. The fluid is sneaking past the piston seal inside the cylinder, moving from the high-pressure side to the low-pressure side. It could also be a control valve that isn’t seating perfectly. Either way, it’s a safety risk. You need to perform a “bypass test” to see if the cylinder is the culprit. If it is, a seal kit usually fixes it.

Q2: Can I just keep topping off the hydraulic fluid instead of fixing the leak?

I mean, you can, but it’s a terrible idea. First, hydraulic fluid isn’t cheap. Second, if oil is getting out, dirt is getting in. By ignoring the leak, you are letting contaminants enter the system, which will eventually destroy your main hydraulic pump and control valves. A $100 seal fix today prevents a $3,000 pump failure next month. Don’t step over a dollar to pick up a dime.

Q3: How do I know if my hydraulic fluid is “bad”?

Look at it and smell it. Fresh fluid is usually clear and amber (like honey). If it looks milky, you’ve got water in it (bad for seals). If it looks black or smells like burnt toast, it’s oxidized from overheating. If you rub a drop between your fingers and it feels gritty, you have particle contamination. Any of these signs mean you need a flush and fill immediately.

Q4: Is it safe to use a sealant tape on hydraulic fittings?

Be very, very careful here. Professional mechanics generally avoid Teflon tape on hydraulic threads because if a tiny shred of that tape breaks off, it travels downstream and clogs a valve orifice. It’s better to use liquid hydraulic thread sealant or, even better, rely on the O-ring and JIC fittings designed to seal without extra goop. If you have a Hezhong Forklift, stick to the OEM sealing methods found in the service manual.

Q5: My cylinder rod has a small dent. Can I file it down?

If the dent is small and has a sharp burr sticking up, yes, you must file it down gently with a fine stone or emery cloth to smooth it out. You want to remove the sharp edge that cuts the seal. However, if the dent is deep, it will still hold a pocket of oil that will bypass the wiper seal every time it strokes. Smoothing it buys you time, but eventually, that rod needs to be replaced.